With open-plan living and under-floor heating becoming part of many projects there are some crucial things to bear in mind. While engineered wood-floors are suitable for use with under-floor heating, there are certain practices that should be observed to ensure both optimal heating conditions and that the installed floor does not have any structural issues in the future.

Is an Area Appropriate for Wood Flooring?

One of the important things to consider is if your project has one area under-floor heated and another area without under-floor heating, it can be a problem to lay one contiguous covering over both areas as several boards may be sitting over both areas and heating one side of an engineered board while the other remains cold can cause the boards to warp or have other structural issues.

While this can be a problem, if the area concerned is a doorway or small area then it can still be possible to run the whole thing through but this would need to be judged on a project-by-project basis.

Concrete Sub-Floors

It is vital when bonding a wood floor to a concrete screed that the concrete has had enough time to dry. If there is too much moisture in the screed then it can lead to the floor de-bonding from the screed, the boards becoming damaged and other such issues.

Fixing Methods

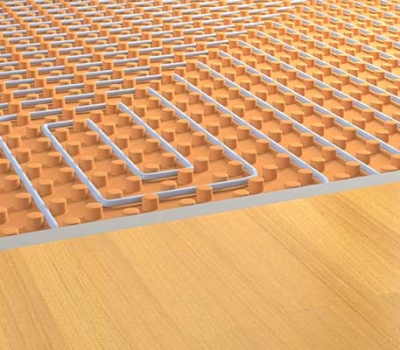

Ideally, with standard wet-systems placed in a concrete screed it is highly recommended to bond the wood floor to the sub-floor using a flexible adhesive, one must never use rigid or water-based glue. One must also ensure that the glue is evenly spread underneath any flooring as this will ensure there are no air pockets as these lead to hot and cold spots on the floor.

Electric Matting Systems

While we generally recommend tongue-and-groove floors for most situations, it can be a good idea to use a click system with electric systems as it will mean the floor can be un-clicked to repair any damage to the system. Also, unlike other floors where we recommend bonding to the sub-floor, in the case of electric systems they are always floated on an underlay. There are several underlay’s available for these systems.

Controlling the Thermostat

When using under-floor heating from cold it is important to gradually increase the temperature, this will ensure that there is no structural damage to the floor. We recommend increasing the heat by a maximum of 5 degrees centigrade every 24 hours, up to a maximum temperature of 27 degrees centigrade.

Floor Choice

When choosing the wood floor for your project, assuming you have under-floor heating you should choose a floor no thicker than around 15mm as this will ensure you are not making the heating work too hard. Something like a 20mm thickness of floor will likely be inefficient at conducting the heat to your room.

At the wood flooring shop we have products that are specifically targeted at under-floor heating, they contain oak on the underside of each board and as oak conducts heat better than just plywood this means better heating for your home.